Partner of your quality approach, Hospitec supports you in the regulatory controls of your welders (heat sealers)

The different stages of a welder inspection

On-site control

Test of the following points:

- programmed sealing temperature

- programmed sealing pressure

- welding width > 6mm

- absence of grooves, folds, chimneys

- seal intact over the entire width and length of the weld

- no delamination or separation of materials when opening the bags

- no bursting of bags during the sterilisation cycle

Control in the measurement laboratory

In the days following the on-site inspection, we carry out pull-out resistance tests in our measurement laboratory on:

- 5 sterilised welds

- 5 unsterilised welds

We thus measure the following data:

- Minimum strain

- Maximum strain

- Medium strain

The ISO11607 standard imposes an average strain value greater than 1.5N

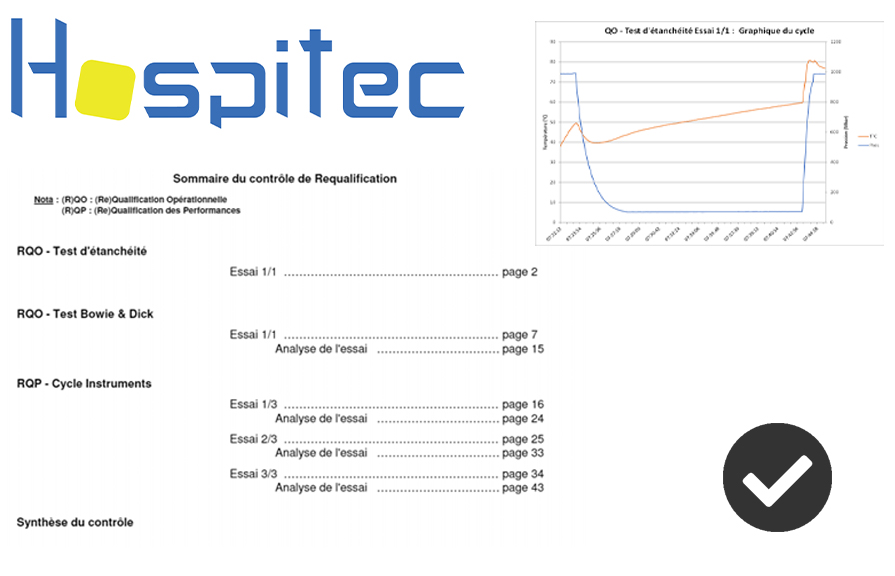

This report contains, among other things:

- A notice of compliance according to the standards

- A comparison between the indications of the welder and our measuring instruments

- Follow-up with comparison of the results of previous tests

- A relevant opinion possibly proposing corrective measures

- A detailed conclusion of the entire inspection